| Item | Plan | Performance | Achievement(%) | |

|---|---|---|---|---|

| Development objective | Develop INNER ROD forging by applying high-strength aluminum material |

Develop A6082Modify high-strength alloy Develop INNER ROD forging (3 type) |

100% | |

| Quantitative Target Item and Achievement |

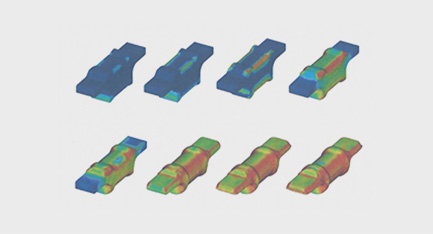

1. Tensile Strength | Over 340Mpa | 358MPa ~ 360MPa | 100% |

| 2. Yield Strength | Over 270Mpa | 328MPa ~ 335MPa | 100% | |

| 3. Product Strength(Z+) deformation | Within yield | OK | 100% | |

| 4. Product Strength(Z-) deformation | Within yield | OK | 100% | |

| 5. Product Strength(X) deformation | Within yield | OK | 100% | |

| 6. X-RAY Inspections | 3 LEVEL ↑ | 1 Level | 100% | |

| 7. INNER ROD RIB Thickness variation | ±0.2 | 0.1 ~ 0.13 | 100% | |

| 8. INNER ROD RIB Thickness variation | ±0.2 | 0.1 ~ 0.13 | 100% | |

| Other Performance | Agreement that INNER ROD is applied from PILOT stage to vehicle. | |||

| Expected effects | INNER ROD parts have been developed by applying high-strength aluminum materials, and existing STEEL products can be substituted. Similar parts (INNER METAL type) can also be extended to high strength aluminum materials. | |||

| Application |

Hi-performance automotive lightweight parts Precise forging High-strength industrial materials |

|||

| number | Classification | TYPE 1 | TYPE 2 | TYPE 3 |

|---|---|---|---|---|

| 1 | Material |  |

|

|

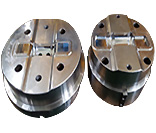

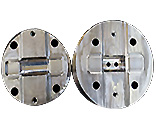

| 2 | Forging Mold |  |

|

|

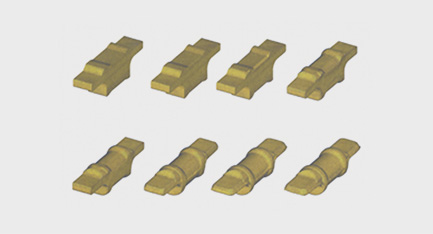

| 3 | Finished Product |  |

|

|

| Product name | Product features (including comparison with existing product and comparative advantage) | ||

|---|---|---|---|

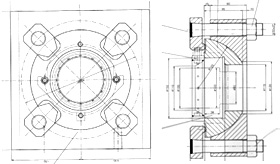

| High-strength precision air-cylinder |

At the same manufacturing cost, mechanical properties are 30% better than existing air-cylinder, and durability can be improved by 50% or more

|

||

|

|

|

|

| Drawing dies Schematic diagram | Plug Type | Drawing dies Tilting Device | |